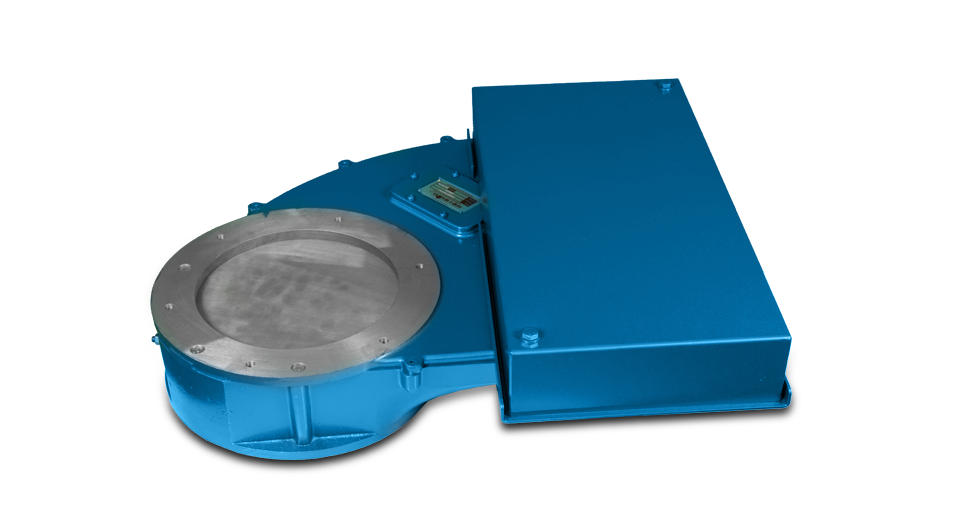

Manufactured in cast aluminium with stainless steel slide plate, the Rotoslide is a compact isolator in manual and automatic version. It is jam-free owing to the pivot operation mechanism and meets the dust containment and cleanliness requirements of most industries by being enclosed at all times. It is sized between 150mm and 300mm.

Slide Valves are used for controlling the flow of powders, pellets and granules from the inlet or outlets of equipment.

Rotolok have been making an extensive range of fabricated units to suit the general industrial fields, but with the ROTOSLIDE, manufactured in cast aluminium with stainless steel trim, the opportunity now exists to cater for the food and chemical industries, an area not previously covered on a production basis.

Why Rotoslide?

Rotolok’s Rotoslide has a different concept than the majority of slide valves marketed, inasmuch that it is truly jam free, and whether it is hand or pneumatically operated the basic principle of using a pivot holds the slide plate in a positive fixed position, while the slide extremity is supported by nylon studs on stainless steel pins.

The conventional slide of pushing a plate relies on exact centralisation of the cylinder to ensure the plate does not veer to the side causing jamming – the Rotoslide overcomes this impracticability. It has been designed to meet the health and safety acts requirements of the slide being always completely enveloped, enclosed and dust tight.

-

Bodies

LM6 Cast Aluminium

-

Slide Plate

Stainless Steel

-

Slide Plate Support

Nylon studs supported by Stainless Steel screws

-

Hand Operated

Positive easy action handle

-

Pneumatic Version

One double acting cylinder rear clevis mounted

-

Solenoid Valve (Pneumatic Only)

2 position 5 port single solenoid spring return

-

Limit Switches

Mounted to indicate open/ closed position. Optional on manual version

All dimensions are in mm unless otherwise stated

| SIZES | A | B | C | D | E | F | G | H | J | K | L | N | P | R | S | T | X° |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 150 | 150 | 230 | 98 | 16 | 12 | 6 | M10 | 195 | 162 | 254 | 268 | 220 | 267 | 425 | 197 | 115 | 0° |

| 200 | 200 | 300 | 98 | 16 | 12 | 6 | M12 | 260 | 245 | 365 | 380 | 208 | 266 | 425 | 197 | 115 | 17.5° |

| 250 | 250 | 350 | 125 | 16 | 12 | 6 | M12 | 310 | 316 | 460 | 474 | 245 | 316 | 440 | 224 | 170 | 17.5° |

| 300 | 300 | 400 | 125 | 16 | 14 | 8 | M12 | 360 | 398 | 566 | 580 | 245 | 316 | 440 | 224 | 170 | 15° |